You can customize forecasting with Restock Profiles based on your product's sales velocity, MOQ, and reserve stock level.

Navigation: Restock Forecasting > Restock Profiles

1. Go to Restock Forecasting.

2. Go to the Restock Profiles tab.

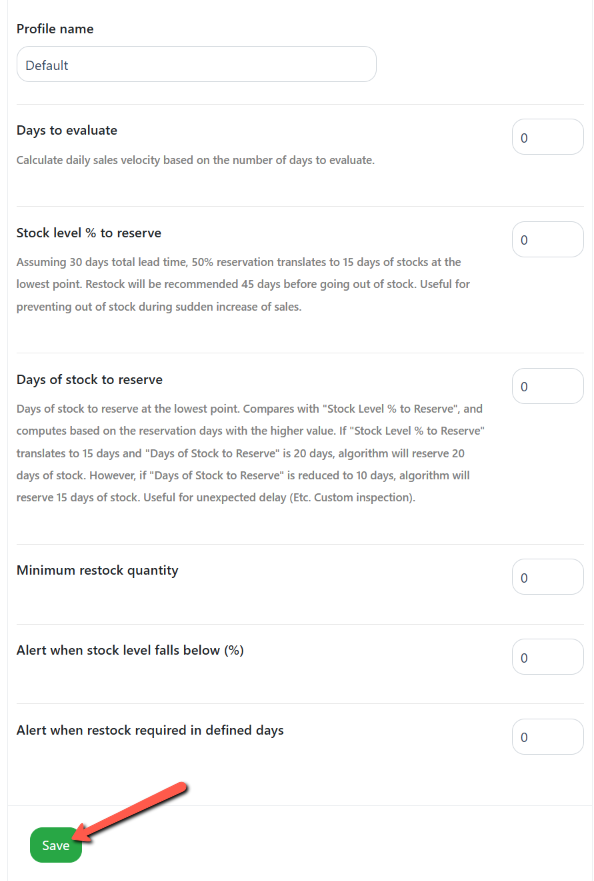

3. Click Create Profile to make a new profile or edit/clone an existing profile.

4. Set the values for the Restock parameters and click Save.

Restocking parameters

1. Days To Evaluate

SI calculates your daily sales velocity based on the number of days you input to evaluate.

2. Stock Level % to Reserve

This feature helps prevent out-of-stock in case of a sudden increase in sales.

It will compute the number of days you need to place an order before going out of stock based on your total lead time and sales velocity (For example, you need to place an order 3 days from now, 100 days, etc.). It will also calculate the quantity to order.

Assume a product with 30 days total lead time (production + freight).

SI will compute how many days of stock to reserve based on the formula:

Example

So if a user puts a 50% reservation, this is how it looks:

30 days lead time * 50% = 15 days of stock to reserve

Let's assume that the requirement is 15 days of stocks at the lowest point.

With a 30-day lead time, SI will recommend restocking 45 days before going out of stock.

3. Days of Stock to Reserve

This feature tells you when and how much you should restock.

It is similar to "Stock Level % to Reserve," except the user input is directly based on days to reserve.

You don't need to fill in both fields; you can just set the one to a "0" value.

If you fill in both, SI will calculate which end up with higher "days of stock to reserve" and recommend restocking based on the higher value.

The numbers will then reflect on the forecasting dashboard.

4. Minimum Restock Quantity

"Minimum Restock Quantity" is the MOQ of the SKU.

So if the MOQ is 1000, but the amount to restock is 800, it will round upwards to the MOQ.

5. Alert When Stock Level Falls Below (%) and Alert When Restock Required In Defined Days

These features alert you when the stock level falls below the specified %.

"Alert When Stock Level Falls Below (%)" and "Alert When Restock Required In Defined Days" control WHEN you will get an alert.

If your lead time is 30 days, and you put 80% on the "Alert When Stock Level Falls Below (%)," this means you'll receive an alert email when you're going to run out of stock in:

30 days * 80% = 24 days.

We suggest setting this at a higher number.

If your stock level to reserve is 50%, you'll probably want to put this value higher than 150% so that you'll get a heads up before needing to place an order.

(You usually don't want to be alerted on the same day if you should have to order stocks. You probably want to get a heads up a few days before you are required to place an order)

Note: If you're using "Days of Stock to Reserve," an easier way is to fill in "Alert When Restock Required In Defined Days."

So if "Days of stock to reserve" is 10 days, and you want to be alerted 5 days before you need to restock, then put "Alert When Restock Required In Defined Days" as 5 days.