- 17 Aug 2022

- 1 Minute to read

How does forecasting work?

- Updated on 17 Aug 2022

- 1 Minute to read

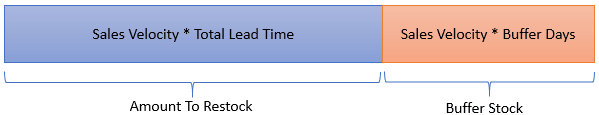

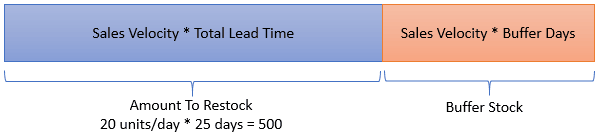

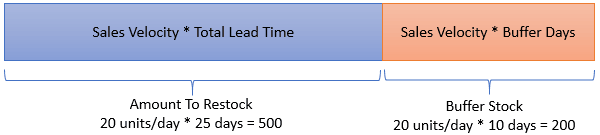

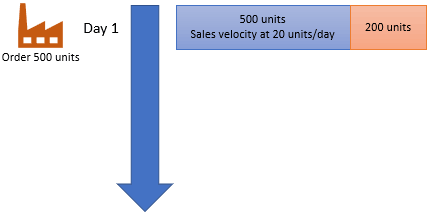

1. The system calculates the amount to restock (Amount to Restock) by multiplying daily sales velocity with total lead time. It calculates the number of stocks to reserve/buffer (Buffer Stock) by multiplying daily sales velocity with days of stock to reserve (Buffer Days).

2. If the daily velocity is 20 units/day and the total lead time is 25 days, the system will recommend ordering 500 units during restocking (Amount to Restock).

3. If you want to reserve/buffer 10 days of stocks to mitigate unexpected delays or increase in sales, the algorithm will attempt to reserve/buffer 200 units at the lowest point (Buffer Stock). It will recommend restocking the day when the stock level reaches 700 units (Amount to Restock + Buffer Stock).

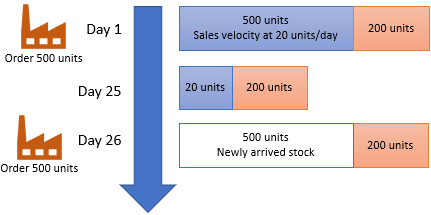

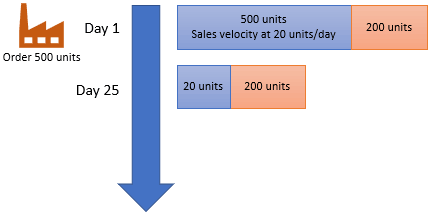

Restocking Timeline

1. Assume 25 days lead time, 20 units/day, and 200 units of reserved stock (Buffer Stock). The system will recommend restocking when 700 units are left.

2. 1 day before stock arrives, there will be 220 units left (assuming daily velocity remains the same).

3. Stock arrives on the 26th day, bringing the total stock level to 700 units. The system will recommend restocking since 700 units are left.